nilsan masala and herbs grinder

Spices That Reflect The Richness Of Our Culture

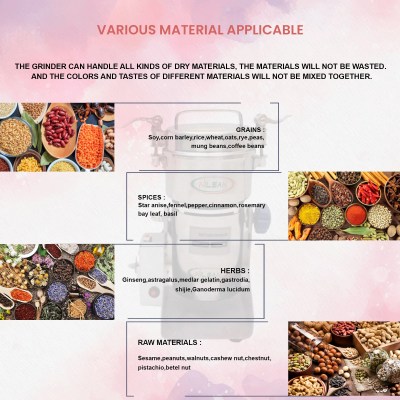

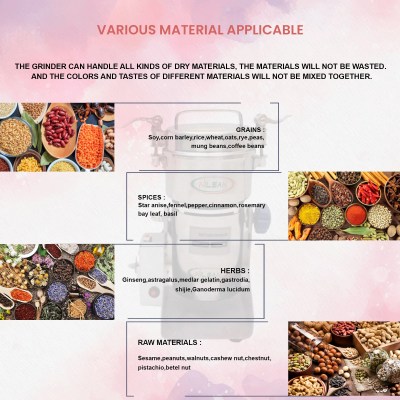

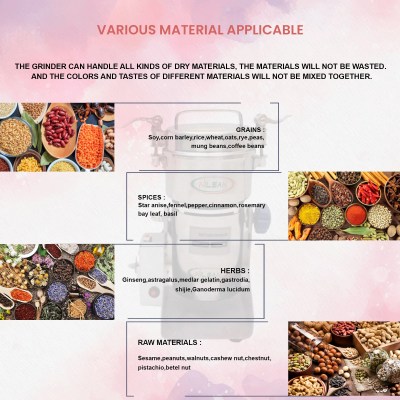

Our Small multi-functional spice grinder, spice grinding machine, corn grinder/corn grinding machine, pulverizer, food grinder, or herb flour powder grinder grinding Machine, features stylish design, energy-saving, and easy operation. The food/ coffee grinder machine is a very good powder processing equipment. It is not restricted by the viscosity of the material’s hardness, softness, fiber, etc., and it can have a better crushing effect for any material.

A multi-functional high-speed powder mill is suitable for grinding dry spice, grain, coffee bean, rice, and anise. It is widely used in supermarkets, laboratories, TCM pharmacies, mills, health clubs, and homes.

Features:

1) Simple structure, easy to install and maintain.

2) Stainless steel material, food-grade security guarantee.

3) Overload protector, 200° high temperature resistant motor, time control switch.

4) 270° swing, maximize the milling efficiency.

5) Fine structure, low noise, small size, no vibration

6) Compact appearance and easy operation

The high-speed multifunction grinder features are adopted the latest technology, with the following features: fine structure, low noise, small size, no vibration, compact appearance and easy operation. It can grind all kinds of corns and grains into fine powder at 50-300 mesh.

Process:

The working time is depending on the material. when you put the material into the cabin, please put it to half of the cabin. The effect will be better. And you should let the material cover the blade at least. If you feel the machine is a little hot. Please let it have a rest.

1. the 20s–spice such as chili, pepper

2. The 20s-30s–bean, such as soybean, rice, corn.

3. The 40s-60s–hard things, such as pearl, roots.

4. about the material with fiber, the fiber cannot be crushed entirely, so their powder will be floccus.

5. about the nuts, and other things with oil.

It’s better to grind 2-3 seconds, then stop. again, grind 2-3 seconds, then stop. again… It’s to prevent the powder stick to the cabin. Because when the machine working, the speed of the motor is very quick, and the material will collide with the blade and cabin, then it will generate heat. And the material is oily, it will stick to the cabin easily.