Small Edible Oil Business Opportunity: Complete Startup Guide

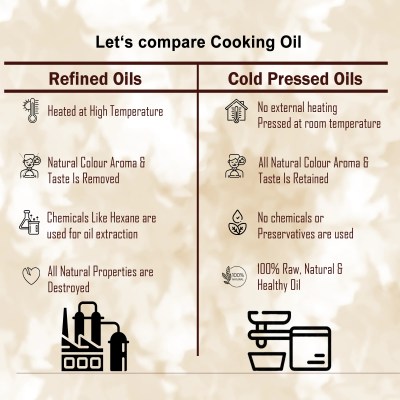

Starting a small edible oil business is one of the best opportunities today. The demand for healthy and pure cooking oil is growing fast in local and international markets. Many people now prefer cold-pressed and natural edible oils instead of factory-refined oils.If you want to begin your own oil manufacturing unit, this guide will help you understand the complete process. With the support of Nilsan Prime India Machines, you can easily set up a small-scale edible oil production business with the right machinery and planning.

Why Start a Small Edible Oil Business?

A small edible oil business can be started with limited investment and gives good profit margins. Edible oils are used daily in every home, restaurant, and food industry.Some popular oils you can produce include:

- Groundnut oil

- Mustard oil

- Sunflower oil

- Coconut oil

- Sesame oil

- Soybean oil

Step 1: Choose the Right Type of Oil

The first step in your edible oil business plan for small scale is selecting which oil you want to manufacture.Before choosing, consider:

- Local market demand

- Availability of seeds

- Production cost

- Profit potential

Step 2: Make a Small-Scale Edible Oil Business Plan

A good business plan is required for a successful start.Your business plan should contain:

- Business objectives

- Nature of oil production

- Target market

- Machines required

- Investment cost

- Marketing plan

- Expected profit

Step 3: Select the Best Location

Location is a significant factor in the production of edible oil.Select a location that has:

- Accessibility to seeds

- Availability of water and electricity

- Accessibility to transport

- Land for machines and storage

Step 4: Buy High-Quality Oil Press Machines

The most important part of starting a small edible oil business is choosing the right machinery.Nilsan Prime India is a trusted Oil Machine Manufacturer offering advanced edible oil production equipment.

The following are some of the most crucial machines needed:

- Domestic Home Use Oil Press Machine

- Mini Commercial Oil Press Machine

- Commercial Oil Press Machine

- Oil Filter Machine and Conveyor

The Oil Filter Machine and Conveyor help improve oil purity and ensure clean, ready-to-pack edible oil.

Choosing the right combination of machines will help you produce high-quality edible oil and grow your business successfully.

Step 5: Installation and Setup

However, after acquiring the machines, proper installation is required for a smooth production process.Nilsan Prime India Machines offers:

- Full support in setting up the machines

- Training on how to use the machines

- Instructions on how to maintain the machines

- Technical support

Step 6: Raw Material and Seed Quality

Good quality seeds produce better oil.Always source seeds that are:

- Fresh

- Clean

- Moisture-free

- Chemical-free

Step 7: Production Process of Edible Oil

The production process of edible oil involves the following steps:- Seed Cleaning

- Seed Crushing

- Oil Extraction using Oil Press Machine

- Oil Filtration

- Storage

- Packaging

Step 8: Packaging and Branding

Packaging is an important factor in gaining customer trust.Use clean and attractive packaging such as the following:

- Plastic bottles

- Glass bottles

- Pouches

- Bulk containers

- Pure oil

- Cold-pressed

- No chemicals

- Healthy cooking oil

Step 9: Marketing Your Edible Oil Business

To grow your small edible oil business, focus on marketing.The best marketing channels include:

- Local grocery stores

- Restaurants and hotels

- Online platforms

- Social media promotion

- Wholesale distributors

Why Choose Nilsan Prime India for Your Oil Business?

Nilsan Prime India is a renowned Oil Machine Manufacturer that offers efficient solutions for small and medium oil units.The advantages are:

- High efficiency in oil extraction

- Robust and easy-to-operate machines

- Feasible business models for small-scale businesses

- Comprehensive after-sales services

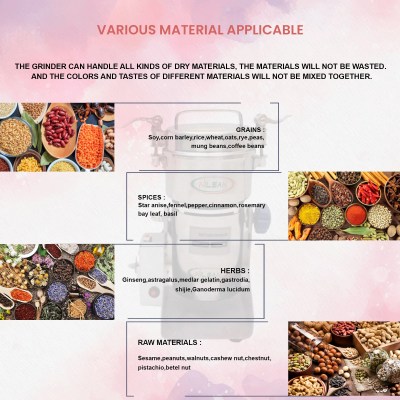

- Versatility to process various oil seeds

Conclusion

Beginning a small business related to edible oil is a great investment opportunity with high demand and growth.With a proper edible oil business plan for small scale, the right equipment, and a trusted oil machine manufacturer like Nilsan Prime India Machines, you can establish a successful oil production unit.

If you are planning to start your business in the edible oil industry, this is the right time to begin with Nilsan Prime India Machines.

Using an Oil Press Machine the Right Way: Mistakes to Avoid

Oil Press Machines are gradually becoming popular these days, especially among individuals who need fresh, healthy, and chemical-free oil for daily consumption at home. Whether you are using the domestic oil press machine for home use or for business purposes, it is necessary to understand the use the machine.Many people buy this machine, but do not get the best results due to small mistakes in the use of the machine. The mistakes may cause the quality of the oil to lessen and the oil yield to reduce. The machine may even get damaged.

In this blog, we will explain the most common mistakes people make and how to use oil press machine correctly for better performance and long-lasting results.

1. Using the Wrong Seeds or Poor-Quality Raw Material

One of the main mistakes is the use of old or low-quality seeds. Seeds that are damp, spoiled, or mixed with dust affect oil extraction.Correct Suggestion:

- Always use clean, fresh, and dry seeds.

- This should be cleaned by removing stones, dirt, and other impurities before pressing.

- The right raw material provides a good output of oil and taste.

2. Not Cleaning the Machine Before and After Use

Most people do not clean the machine after use. Oil and seeds can build up inside the machine.This can lead to:

- Blockage

- Bad smell in the oil

- Reduced machine efficiency

- Clean the pressing chamber regularly.

- Remove leftover sediments after every batch.

- Proper cleaning increases machine life.

3. Pressing Seeds Without Proper Drying

The major cause of low oil extraction is moisture content. Excessive moisture content in the seeds decreases the yield and may cause cloudy oil.Correct Tip:

- Dry the seeds either in the sunlight or by using a dryer.

- Moisture levels should be optimum to enable easy extraction.

- This is especially important if the cold oil press machine is used, as the temperature will be low.

4. Overloading the Machine

Most individuals assume that the more seeds they add at a single time, the sooner they will get the oil. However, overloading the seeds can result in:- Motor Stress

- Jamming

- Uneven pressing

- Follow the recommended feeding capacity.

- Seeding should be done slowly.

- This ensures smooth operation and the flow of oil.

5. Ignoring Temperature Settings

Some machinery may be able to control temperature. Temperatures that are not appropriate can impact the quality of the oil- High heat may damage nutrients.

- Low levels of heat may hinder oil production.

- For healthy oils, a cold oil press machine can be used.

- Maintain proper temperature depending upon the seed type.

6. Not Filtering Oil Properly

Further, after pressing, oil generally contains seed particles, sediments, and impurities. Some users store oil without filtration.This may cause:

- Shorter shelf life

- Bad taste over time

- Allow the oil to settle naturally.

- You may use a filter cloth or oil filter machine for the process of purification.

- Clean oil is more visually appealing and lasts longer.

7. Skipping Regular Maintenance

As can be expected from any piece of machinery, an oil press needs to be maintained regularly. Failure to do so can cause damages to the equipment, which can be very expensive.Correct Tip:

- Check screws, parts, and motor condition monthly.

- Lubricate moving parts if required.

- Replace worn components on time.

8. Using the Machine Without Reading Instructions

Many humans use the machine without being aware of the various aspects. This implies that they are using the machine incorrectly.Correct Tip:

- It is very important to read the user manual carefully.

- Familiarize yourself with seed compatibility.

- Before you begin, learn the proper use of the oil press machine.

9. Pressing the Same Seed Continuously Without Rest

There may be overheating of the motor, which is not desired in domestic machines.Correct Tip:

- Give the machine a break after continuous use.

- Avoid pressing for many hours non-stop.

- This is very important for a Domestic Oil Press Machine used at home.

10. Storing Oil Improperly

In spite of producing high-quality oil, wrong storage can spoil it quickly.Correct Tip:

- Store the oil in clean, airtight glass or steel containers.

- Keep it away from sunlight and moisture.

- Use dark bottles for better preservation.

- The proper storing of oil keeps it fresh and healthy.

How to Use Oil Press Machine Correctly

To get the best results:- Use clean and dry seeds

- Avoid overloading

- Clean the machine regularly

- Filter oil before storage

- Maintain proper temperature

- Follow machine instructions

Conclusion

Oil press machines are a good investment for both homes and businesses. There are a number of minor errors that can have a negative impact on the efficiency and longevity of the machines.Whether you are making oil with cold oil press machines for healthy oil production or domestic oil press machines for household needs, the key to success lies with proper operation.

By avoiding these common mistakes, you can enjoy fresh, pure, and natural oil with better performance and long-term savings.

Complete Guide to the Oil Extraction Process from Seeds

Oil extraction is one of the oldest and most applicable processes in the world. In both home cooking and large-scale industrial processing, sesame oil is widely used for its health benefits, flavor, and nutritional value. Peanut oil and sunflower oil require wide application due to their healthiness, flavor, and nutritional value. These oils are crucial in daily cooking and also demanded in considerable amounts for commercial food production.Today, many people and businesses want to understand the oil extraction process in a simple and practical way. Whether you are planning to extract oil at home or want to start a small oil business, learning the basic steps is very helpful. With the right method and equipment, oil extraction from seeds can be done efficiently while maintaining good quality.

In this guide, we will explain how oil extraction from seeds works, what machines are used, and the complete process from seed preparation to final oil filtering.

What is the oil extraction process?

The oil extraction method is the process through which oil is extracted from the seeds that are rich in oil. Some of the commonly used oil-rich seeds for oil extraction include sesame seeds, peanut seeds (also known as groundnuts), and sunflower seeds. All these seeds are naturally rich in oil, and through the right oil extraction methods, oil can be extracted safely for usage.There are different ways of extracting the oil, some of which involve the use of traditional techniques like cold pressing, whereas other methods involve the use of devices like an oil-making machine. Most businesses today prefer using an oil extraction machine, as the traditional method is quite old and is not considered as fast, clean, and efficient as the use of a machine.

Types of Seeds Used for Oil Extraction

Different seeds produce different types of oils, each with its own taste, smell, and benefitsSesame oil is known to be full of flavor and is mainly used as a cooking oil in Asian food. Peanut oil is often employed for frying, as it has a mild taste and a high smoking point. Sunflower oil is light and healthy and is among the most utilized oils for cooking.

Understanding the type of seed helps in selecting the appropriate extraction method and the right oil machine for efficient oil extraction.

How to Prepare Seeds for Oil Extraction

1. Seed Selection & Cleaning

The first and most important step in the extraction of oil involves selecting high-quality seeds. Fresh and mature seeds should always be selected, avoiding seeds that are spoiled and infected with fungus. Low-quality seeds can result in a reduction of oil content and purity.Once the selection of the oil seeds has taken place, cleaning of the seeds to get rid of any impurities, such as dust, stones, leaves, and other undesirable materials, needs to be conducted. Cleaning of oil seeds enhances the quality of the oil, as well as providing a protective mechanism for the oil extraction machine. Some of the oil extraction machines used for the cleaning process include sorting machines.

2. Drying & Moisture Control

After cleaning, seeds must be completely dried prior to extraction. Control of moisture is a key factor in producing clear and high-yield oil.Excess moisture in seeds reduces oil yield, and such extracted oil may appear cloudy. Drying can be natural in sunlight for small-scale production or mechanical using drying equipment for large-scale operations.

3. Crushing & Optional Roasting

Most of the time, the seeds, like peanuts and sunflowers, have to be crushed or grounded before pressing. Crushing the seed is important since it enables a smooth flow of the oil.Roasting is another optional step, and it is mainly applied to sesame seeds or peanut seeds. It enriches the flavor, aroma, and content of the extracted oil. However, roasting is not applied to sunflower seeds because they are preferred for their light or mild taste.

Oil Pressing Using an Oil Machine

The most crucial process at this stage is oil pressing using an oil machine. At this period, oil extraction takes place from the seeds using a sophisticated oil making machine with great pressure capability.Oil can be extracted in two main ways:

- Cold pressing does not use heat; therefore, the oil extracted has more nutrients, making it a healthier choice. Hot pressing uses heat before oil extraction, resulting in greater oil content and a stronger oil taste.

- Businesses today prefer automated oil machines because they offer higher precision and save time. The use of a high-quality oil machine results in faster oil extraction and provides more efficient results, making it suitable for use by both individuals and businesses.

Oil Filtration and Purification

In addition, after pressing, oil contains seed particles, dirt, and unwanted material that are naturally present in the oil. So, the oil needs filtering and cleaning.The process of oil filtration can be done through the use of oil filter press machines, cloth filtration in small-scale industries, or a vacuum oil filtration system in large-scale businesses. Filtration ensures that the oil is clear and ready to be sold.

Storage of Extracted Oil

Once the oil is filtered, proper storage is required to maintain its freshness and quality. Proper storage includes storing oil in stainless steel containers, food-grade plastic bottles, or dark glass bottles for premium quality oil.The storage areas should also be cool and free from sunlight, heat, and moisture. Proper storage will help extend the oil’s flavor, fragrance, and nutrients.

Benefits of Using an Oil Making Machine

Some advantages of the use of modern oil-making machines are faster extraction, higher oil content, purity, and quality.The oil machines are best for use in both small businesses and large-scale production. They are easy to use and maintain, making them a worthwhile investment for any individual seeking to start in the oil industry.

Conclusion

The process of extracting oil using sesame seeds, peanut seeds, and sunflower seeds is simple if one undertakes it in a step-by-step manner, where every single stage in the process is essential in obtaining quality oil meant for consumption.Hence, it is possible to extract oil from seeds with the help of a reliable oil machine. Once you are eager to start oil production, understanding this entire process of oil extraction from the machine is essentially required.

5 HP Pulverizer Machine: Complete Guide

A 5 hp pulverizer machine is a powerful industrial grinding solution used for crushing and pulverizing a wide range of materials into fine powder. Due to its high efficiency, compact size, and consistent output, it is widely used in food processing, spice grinding, chemical industries, and small-scale manufacturing units.In this blog, we will explain what a 5 hp pulverizer machine is, its capacity, applications, and why it is a smart investment for your business.

What Is a 5 HP Pulverizer Machine?

A 5 HP pulverizer machine uses an electric motor to grind raw materials into fine powder through high-speed impact and friction.These devices offer the ideal balance between performance, longevity, and energy efficiency and are designed for medium-scale production.

Modern models, such as the Pulverizer 5HP 2 in 1 Double Chamber, allow grinding in two stages, improving output quality and productivity.

How Does a 5 HP Pulverizer Machine Work?

The operational procedure consists of- Using the Feeding Chamber to feed raw materials

- The material is crushed by fast-rotating Grinding Mechanism or blades.

- Powder fineness is controlled by sieves.

- After grinding, the ready powder is smoothly discharged from the machine.

This grinding process ensures uniform particle size, minimal material loss, and smooth continuous operation, making the machine suitable for long production cycles.

Capacity of 5 HP Pulverizer Machine

The type of material, moisture content, and required fineness all affect a 5 HP pulverizer machine's capacity.- The range of average capacity:

- 20–30 kg of spices per hour

- Pulses and grains: 25–40 kg/hour

- Dry leaves and herbs: 15–25 kg/hour

- Minerals and chemicals: 30–50 kg/hour

Machines like the Pulverizer 5HP 2 in 1 Double Chamber Pulverizer are ideal for commercial use, offering higher efficiency and consistent output.

A 5 hp pulverizer machine is used across multiple industries due to its versatility.

Applications of 5 HP Pulverizer Machine in the Food Industry

- Spice grinding (chilli, turmeric, coriander, cumin)

- Flour and grain milling

- Sugar, salt, and dry food powder processing

Ayurvedic & Herbal Industry

- Dry herbs and roots

- Leaves and medicinal plants

- Ayurvedic and herbal powders

Key Features of a 5 HP Pulverizer Machine

- Heavy-duty 5 HP electric motor

- High grinding efficiency with uniform output

- Compact, sturdy, and vibration-free design

- Low maintenance and easy operation

- Energy-efficient performance

- Customizable mesh size for desired fineness

- Suitable for continuous and long-hour production

Modern Pulverizer systems are designed for long-term industrial usage and reliability.

Benefits of Choosing a 5 HP Pulverizer Machine

- Perfect for production on a medium scale

- A solution that is both economical and energy-efficient

- Consistent quality and high productivity

- Simple setup and easy to use

- Extended service life with little downtime

Why Our Pulverizers Stand Out

- Usage of high-quality raw materials

- State-of-the-art manufacturing and quality control

- Customized pulverizer solutions

- Competitive pricing with high durability

- Unmatched after-sales service and support

We are experts in machines such as the Pulverizer 5HP 2 in 1 Double Chamber Pulverizer to provide unmatched efficiency and durability.

How to Choose the Right 5 HP Pulverizer Machine

Before purchasing a 5 hp pulverizer, consider:- Material to be pulverised

- Capacity per hour

- Fineness of powder

- Space where the machine is to be installed

- Cost of the machine and future expansion

Conclusion

A 5 HP pulverizer machine is a great investment for those businesses looking for an efficient grinding process. With the right features and build quality, it becomes a great asset for food processing, chemical, agricultural, and herbal businesses.If you are searching for a robust and high-performance pulverizer machine, NILSAN PRIME INDIA PVT. LTD is a great option for you.

Commercial Oil Press Machines Subsidy: Eligibility & Benefits

With the rising demand for cold-pressed and chemical-free edible oils, Commercial Oil Press Machines have become a profitable investment for entrepreneurs, oil mill owners, and agro-based businesses in India. To encourage large-scale oil production and support the Make in India initiative, the government offers up to 35% subsidy on commercial oil press machines, especially for (heavy-duty) commercial machines.The following is a guide to everything you need to know about the 35% subsidy on commercial oil press machines, the benefits available from the government, the application process, and also why investing in a large commercial oil press is a great idea from a business standpoint.

Understanding Commercial Oil Press Machines

Commercial Oil Press Machines are industrial-grade machines that are designed to function as machines intended to carry out constant large-scale oil pressing processes. Unlike other oil presses, which are designed for small-scale use, these machines are designed to meet the operational needs of commercial oil plants, food processing plants, and agro-industrial plants in general.commercial oil press are capable of handling large quantities of oil seeds with regular results, reliability, and long life. They are used for the extraction of oil from the following oilseeds:

- Groundnut

- Mustard

- Sesame

- Soybeans

- Sunflower

- Coconut

- Cottonseed and other oilseeds

Overview of 35% Government Subsidy

To promote value addition in agriculture and reduce dependence on imported edible oils, the government provides financial assistance of up to 35% for the purchase of Commercial Oil Press Machine. This subsidy is available through a variety of schemes that are classified as- Agriculture and allied activities

- Food Processing Development

- MSME and Rural Entrepreneurship

- Farmer-Producer Organizations (FPOs)

It is important to note that the subsidy applies only to large commercial oil press machines and not to small, domestic, or household units.

Benefits of Subsidy on Commercial Oil Press Machines

1. Reduced Capital Investment

Considering the subsidized amount of 35%, the initial costs involved in installing the commercial oil press unit will be manageable for young and growing businesses.2. Improved Business Viability

Additionally, lower equipment costs paired with high production efficiency make oil extraction ventures more viable in terms of returns from investments.3. Support for Large-Scale Production

Manufacturing oil pressing machines for commercial purposes have been invented to ensure the operation continues relentlessly in the production of the commercial oil.4. Encouragement of Agro-Industrial Growth

It encourages rural employment and participation through supporting the structures used for extracting oil from the farm produce.5. Long-Term Operational Stability

Unlike the oil presses used by individuals, heavy-duty oil presses are not only long-lasting but also require little replacement.Adaptability for Multiple Oilseed Processing

Commercial Oil Press Machines are engineered to efficiently process a wide range of oilseeds without compromising extraction efficiency or oil quality. Their advanced mechanical design allows smooth handling of different seed sizes and oil content levels, ensuring consistent performance across various raw materials. This adaptability enables commercial oil mills to diversify production, respond to changing market demand, and maintain uninterrupted operations throughout the year. By supporting multi-oilseed processing, these machines enhance operational flexibility and contribute to long-term business stability and profitability.Application Review & Subsidy Disbursement Procedure

After submitting the application through the respective government department or scheme portal, the application is assessed on the basis of documentation, project feasibility, and descriptions related to machines. In some cases, a physical verification of projects might also be done. After approval of the application, an amount of 35 percent is allocated based on government schemes and norms. The approved subsidy amount is either transferred directly to the beneficiary’s bank account or adjusted against a portion of the commercial oil press machine cost, as per scheme guidelinesImportance of Large Commercial Oil Press Machines

Large capacity commercial oil press machines play an essential role in satisfying oil extraction demands. It ensures that large quantities of oil of considerable quality and extraction rates are produced. It reduces the cost of oil produced from various oil crops. Therefore, it creates an environment that favors business efforts in oil mill services.Choosing a Trustworthy Commercial Oil Press Manufacturer

When investing in heavy-duty industrial machinery, selecting a reliable manufacturer is essential to ensure compliance with subsidy guidelines, robust engineering standards, and dependable technical support. A trusted manufacturer contributes to consistent performance, operational stability, and long-term reliability of commercial oil press machines. Nilsan Prime India is recognized for providing commercial oil press solutions designed to meet industrial requirements while supporting structured and sustainable oil extraction operations.Conclusion

The 35 percent subsidy on machines such as Commercial Oil Press Machines is an excellent opportunity for entrepreneurs to explore. This policy aims to encourage entrepreneurs to establish larger oil press machines to improve edible oil production within the country.By investing in a business oil press machine with a subsidy, not only is financial pressure eased, but also a path towards business efficiency, profitability, and sustainability is created within the burgeoning business of oil processing in India.

Modern Cold Press Oil Machine for Optimal Performance

The pressing technology applied in our high-efficiency cold press oil machine makes it capable of extracting the natural oil while preserving the important ingredients of the fruits or seeds being pressed. This technology also makes our machine produce a large quantity of oil with little heating. The machine is suitable for business operations and small businesses, as it offers advantages such as reduced power consumption, stronger processing, and easy use. The machine is suitable for various oil seeds and makes an appropriate investment to ensure successful oil extraction.1. Maximum oil output with minimal power usage

Nissan Prime India is among the most renowned and trusted brands in making high-performance cold press oil machines, with a guarantee of durability, efficiency, and pure oil extraction. Our oil press machine is designed with an efficient and strong system, using less power and producing maximum results. The home, miniature, and heavy oil press machines are designed with technologies most appropriate for each oil-bearing seed and nut. At Prime India, we are into the oil press machine business and other products related to it. innovation-driven and sustainable company. In this case, at Nilsan Prime India, our goal is to provide the effective and affordable range required by the food processing industry.The cold oil press machine for homes that we have available is created in a manner that is both easy to use and efficient. It is for use in homes and enables a consumer to make healthy oil from whatever seed they desire. Additionally, it is energy-saving and makes no noise.

2. Eco-Friendly Approaches for the Food Processing Sector

Our solutions for the food processing sector lie in efficiency, waste, and sustainability for production. Nilsan Prime India creates cold press oil machine presses that use low power, keeping natural constituents intact, leaving a low environmental footprint. We use strong materials, along with the latest technology, that work towards a cleaner process for healthy food systems, thereby representing sustainable methods for businesses as well as households.Cold press oil extractors consuming lower amounts of energy

- Cold press oil extractors consuming lower amounts of energy

- Low production of heat to retain nutrients.

- Reduced waste generation with green processing

- Strong and durable for prolonged machine life

- promotes the use of sustainable food production practices

3. Cutting-Edge Technology for Reliable Oil Extraction

Advanced technology drives oil extraction solutions at Nilsan Prime India. Our cold oil press machine and cold press oil expeller function at low temperatures, thereby yielding oil that is rich in nutrients and free from chemicals. The cold oil press machine for home uses advanced pressing technology, ensuring a higher yield and less consumption of power. The cold oil press machine for the home uses advanced pressing technology, ensuring higher oil yield and less power consumption. This cold press oil expeller machine has advanced pressing technology, ensuring higher oil yield and less power consumption.With every oil press solution we manufacture, reliability sits right at the core. Our machines are designed for durability, low maintenance, and user safety to ensure that such dependability can be achieved by a business or family alike. For home users, performance and longevity can be further optimized by following best practices outlined in our guide, Top 20 Expert Tips for Using an Oil Maker Machine at Home, for proper use, cleaning, and seed selection. Nilsan Prime India's approach to providing clients with cutting-edge oil extraction technology that promotes long-term operational efficiency and a healthy lifestyle combines innovation, eco-friendly design, and professional advice.

Creative Cold Press Solutions for Homes & Businesses

Nilsan Prime India is the one-stop solution for innovative cold press units to supply oil needs of households as well as heavy-duty industries. Keeping the low-temperature aspect intact, our cold press oil machines press the oil in such a way that the natural nutrients, fragrance, and other characteristics of the oil remain intact. Besides, energy is conserved with these high-tech and elegantly built machines that not only can reach maximum oil extraction but also save energy and have a long service life. At Nilsan Prime, our solutions include compact designs suitable for residential and home use, as well as industrial models with higher extraction capacity for industrial use. All these models of cold press oil machines are multi-seed compatible, making the processes easy and eco-friendly.Each one of our cold press oil machines is a masterpiece of functionality and hygiene.

design principles. Our machines are capable of being run in a domestic setup as well as a heavy industrial atmosphere, enabling the production of oils that are free from any kind of chemicals with the implementation of green oil press methods.

1. Intelligent Oil Press Equipment Made to Meet All Needs

Our smart oil press machine is designed to serve various needs in both home and business use. Every cold press oil machine is designed to ensure efficient extraction at low temperatures to retain natural ingredients. For in-home use, our cold oil press machine for home comes with a space-saving, easy-to-use, and efficient design, making it possible to extract fresh and chemical-free oil.- Intelligent cold press oil machine for smooth performance

- Cold Oil Press Machine for Home Use Introduction Compact design, easy operation

- This is low-temperature extraction intended to give high yields of pure and nutritious oil

- Energy efficiency with little maintenance

- Suitable for multiple oil seeds and daily use

2. Efficient Cold Press Systems for Everyday Home Use

Our home-use cold press systems are also carefully designed with the intention of providing fresh and chemical-free oils that contain nutrients and using simple technology too. The systems have friendly operational controls, they do not produce much noise when operating, and they also have simple designs that fit well into a home setting, making them ideal for health-conscious homes that require purity and efficiency when it comes to extracting oils from seeds and nuts.3. High-Performance Cold Press Solutions for Commercial Needs

With features catering to commercial operations, our high-performance cold press machines serve well in terms of efficiency and durability. The equipment is designed by incorporating powerful material and the latest technology that helps it run continuously in oil mills or commercial entities or food production units. The equipment will perform efficiently, be less of a maintenance burden, and help scale production in commercial ventures that may be focussed on quality or profitability factors.Conclusion

Nilsan Prime India is the renowned brand in the manufacture of the cold press oil machine, bringing smart, efficient, and environmentally friendly solutions to the home as well as the industry. Whether talking about the small cold oil press machine for home use or the latest technological solutions for the industry, the emphasis is on innovative, long-lasting, and comparative solutions.

NILSAN's oil mill machines offer a combination of mechanical engineering design, precision craftsmanship, and user-oriented efficiency; to be more specific, the company is known for its innovation and engineering excellence. Yet, what actually goes on backstage? What is the procedure through which a modern oil mill machine changes the raw seeds into pure, high-quality oil? How to use an oil press machine and how nilsan stand out.

Why Oil Mill Machines Are Important

As the number of people wanting cold-pressed, chemical-free, and nutrient-rich oils keeps rising, selecting the right machine has become a decision of great importance in the case of oil manufacturers. Machines of good craftsmanship in the shape of oil mills guarantee:- Maximized extraction rates

- Oil quality that is more uniform

- Reduced maintenance costs

- An operation that is cleaner and safer

- Equipment that lasts longer

Learn more about the oil mill machine: Top 5 Advantages of Using an Oil Mill Machine

Step-by-Step Guide: How To Oil Mill Machine Works

Oil can be extracted from the various seeds. Each seeds require different processing conditions. Here are oil mill working process:Step 1: seed processing Extracting oil from seeds requires, first and foremost, the right treatment of the seeds, which consists of cleaning (for dust and stones), drying (to get the right moisture), and sorting (for uniformity in size). The above-mentioned process gets seeds ready for the NILSAN machines in such a way that a higher oil yield and a smoother texture are obtained as a result, respectively.

Step 2: feeding system The seeds are fed into the machine automatically, which guarantees the continuous flow, nothing but the right pressure, and no clogs. The feed rate must be constant in order for the machine to work at maximum efficiency, and the NILSAN machines are perfectly built for this.

Step 3: crushing and pressing NILSAN's oil mill machines use high-pressure mechanical pressing and precision engineering to extract oils from seeds as their first stage of extraction. The seeds are carried through a screw shaft, where the pressure increases gradually to the point that the oil oak is separated by friction and compression. The oil is drawn off through channels while the seed cake is pushed out at the end, with the oil's fragrance, taste, and nutrients preserved.

Step 4: oil filtration NILSAN's filtration systems incorporate fine mesh filters, pressure filtration, and cooling stabilization after pressing to remove seed residues from extracted oil, leading to a clean product that passes industrial standards and meets consumers' expectations.

Step 5: cake discharge The remaining seed cake is a byproduct of great value that can be used for animal feed, organic fertilizer, and biomass fuel. The machines of NILSAN are constructed to discharge cake with great efficiency, so the process can continue without blockages or downtime.

Why Nilsan Oil Mill Machine Stands Out

Robust Build Quality NILSAN machines are made from high-strength metals, robust components, and corrosion-resistant designs, which are able to provide a long operational life even when daily use is heavy.Energy efficient NILSAN oil mill machines are energy-efficient, thereby consuming less power, providing more production at the same cost of energy, and reducing the overall costs of operation, which makes them ideal for both small and large-scale production.

User friendly These machines provide the easiest and safest operation through the most user-friendly controls with the accessibility of maintenance. Even the new operators find it simple to learn and manage the NILSAN systems.

Excellent quality The NILSAN machines maintain the same level of extraction with the least difference regardless of whether the oil being extracted is of groundnut, sesame, coconut, mustard, or sunflower.

Low maintenance The design of NILSAN puts emphasis on fewer moving parts, easy-to-replace components, and low wear-and-tear engineering, which translates into shortened downtime and prolonged performance cycles for the businesses.

Conclusion

Oil extraction succeeds as a process only when it is accompanied by precision engineering and a full understanding of processing behavior. NILSAN India merges these aspects into its manufacturing process using efficient, powerful machines that are made for the industrial sector, emphasizing the high-tech aspect of modern-day oil production.

What is a Pulverizer?

A pulverizer is a high-performance machine used to crush, grind, and pulverize material into fine particles. These machines play a critical role in food processing. A Pulverizer ensures efficiency and quality, which maximizes the waste.Types of Pulverizers

Nilsan India offers six types of pulverizers, namely:- Pulverizer 2HP 2 in 1

- 3 HP Pulverizer Machine

- Pulverizer 3HP 2 in 1 (JUMBO) Double Chamber

- Pulverizer 5HP 2 in 1

- Pulverizer 5HP 2 in 1 Double Chamber

- Pulverizer 7.5HP 2 in 1 Double Chamber

How a Pulverizer Works

Pulverizers break down materials through a combination of impact, friction, and pressure. The following is the simple procedure:1.Material Feeding The hopper receives the raw material. 2.Grinding Chamber Activation The material is crushed by high-speed rotating blades, hammers, or rollers. 3.Particle Sizing The final fineness is controlled by screens or classifier plates. 4.Powder Collection The fine material is discharged through discharge outlets or cyclone collectors.

Key Features to Look for in a High-Quality Pulverizer

Machine upgrading or a first-time purchase, pulverizer grinder must-have features are as follows:- High RPM Motor Finer powders and quicker grinding result from high rotations.

- Sturdy Stainless-Steel Body Prevention of contamination and corrosion is important for the food and pharma industries.

- Dust-Free Grinding System It is important for hygiene, safety, and efficient powder collection.

- Multiple Sieves for Particle Control Fine, medium, or coarse powder can be switched.

- Low Power Consumption Operating costs are reduced due to the use of energy-efficient motors.

- Easy Maintenance Quick-clean designs save downtime and labor.

- Cyclone / Blower Systems They help to discharge speed and reduce heat generation.

Such modern, durable, and high-efficiency pulverizers are capable of seamless production and brands like Nilsan India are manufacturers of them.

Here’s a step-by-step approach:1. Identify Your Material Is it dry, wet, fibrous, hard, or sensitive to heat? 2. Decide on the Required Fineness Output microfine, fine, medium, or coarse? 3. Estimate Your Daily Production Needs This will determine your selection of HP and machine capacity. 4. Hygiene and Food-Safety Requirements Determined Stainless steel is a requirement for consumables. 5. Factor in Your Space & Financial Resources For small setups, compact models are available, while heavy-duty versions can drive industrial lines. 6. Manufacturer Selection of a Trusted One A recognizable brand guarantees reliability, better warranties, and after-sales support. For example, explore the Pulverizer Machines collection at Nilsan India here: https://nilsanindia.com/pulverizer/

Conclusion

The right pulverizer is not just a machine but an investment that increases the quality of the product, efficient utilization of the plant, and expansion of the enterprise's production capabilities. By knowing the different types, power ratings, features, and operational needs, you can pick the machine that best fits your business objectives with assurance.If you are searching for long-lasting, high-performance pulverizers with excellent engineering, then check out the entire range at Nilsan India and modernize your processing line with technology that produces uniform results.

Why Choose an Oil Making Machine for Home?

Having a personal Best oil making machine for home is not just a matter of convenience; it is a matter of health. This small and user-friendly gadget ensures that only natural, fresh, and nutrient-rich oils are consumed by you and your family. The oils produced with this machine, unlike the store-bought ones, are rich in their natural aroma, flavor, and essential nutrients.Housewives will find this machine to be a very useful appliance. You may be making peanut oil, coconut oil, sesame oil, or sunflower oil—the whole process is easy and efficient. You can take oil out of various seeds and nuts with only one machine to meet your family's needs.

Nilsan India’s Premium Oil Making Machine

Nilsan India is a reputable brand celebrated for its creative engineering and long-lasting machines. The company's premium home Oil Filter Machine is characterized by its high efficiency, dependability, and user-friendly appearance.1. Revolutionary Cold-Press Technology

This apparatus employs the slowest, natural extraction techniques, thereby ensuring that the temperature does not rise and the nutrients are not lost. This leads to the production of the oil, which has the truest smell, the best taste, and the most health benefits.2. Top-Notch Food-Grade Materials

The machine, made of stainless steel and components that are safe for food contact, guarantees that your oil will be entirely clean during the whole process.3. User-Friendly

All you have to do is put in your seeds, press the button, and the machine will take care of the rest. Even novices can produce perfect oil without any technical skills or knowledge.4. Low Noise & Energy Efficient

It has been designed keeping in mind home use; thus, it works silently and consumes very little electricity—ideal for daily use.5. Compact & Chic

The smooth, small design of the oil extractor blends perfectly into contemporary kitchens. It is an appliance that will be loved for displaying rather than hiding away.6. Simple to Clean

The parts that can be removed and the smooth finish make cleaning very easy—a big benefit in comparison to the traditional home oil-making setups.7. Superior Oil Extraction Rate

Effectiveness is the key. The appliance from Nilsan India ensures that your ingredients will give you the maximum yield, thus saving you time and increasing the value.Key Benefits of NILSAN Oil Making Machine

Compact & Stylish Design:

Designed to be very small, it can be placed easily in any home kitchen.Cost-Effective:

Around 21,000 rupees is a price range that is not too high for any family that wants to go for more healthful options.Low Maintenance:

Just a little bit of effort and cleaning every now and then and it will be perfectly stored and maintained.Multiple Seeds Compatibility:

Compatible with all kinds of seeds such as sesame, groundnut, sunflower, soybean, walnut, etc.Healthy Living:

Pure oil is delivered with no additives or chemicals.How the Oil Making Machine Works

Step 1: Select seeds or nuts.Step 2: feed them into the press.

Step 3: Collect your fresh oil.

Step 4: Store the oil.

Note: Get To Know More About Oil Press Machine Maintenance.

How Ideal Oil Making Machine For Home And Small Business

NILSAN offers an oil extraction machine for home and business. For home: Better healthEnjoy natural flavor

Experiment with different seeds

Avoid chemicals and preservatives

For small businesses: Start a cold-pressed oil brand

Cater to a local business

Sell fresh oil

Low startup cost

Conclusion

The increase in demand for oil making machines in India is one way to see that more and more people are concerned about the quality of oil they consume. The NILSAN NS-TC-600 Model comes across as a potent, economical, and user-friendly device for not only the family but also for small-scale entrepreneurs. If you are in search of a machine that not only saves you but also lasts long and gives you health benefits, then this is the right pick. Take home the comfort of extracting your oil and nature's goodness in every drop of oil.

20 Expert Tips for Oil Maker Machine For Home

1. Choose the Right Seeds and Nuts:

Use only the most excellent quality seeds or nuts that are totally clean, dry, and non-processed. Stay away from moldy, wet, or cracked seeds; they will not only lower oil yield but also cause damage to your machine.2. Check Moisture Levels:

Seeds with too much water content will give less oil. To avoid this situation, sun-dry your seeds for a few hours before sowing to ensure better output and smoother operation.3. Maintain Proper Temperature:

Usually, the top rated oil maker machines run at an ideal temperature range. Do not stress the motor by overloading or overheating it—this way, your oil will be rich in nutrients and have a natural aroma.4. Don’t Overfill the Hopper:

Adding too many seeds at once can cause clogging. To avoid forcing the machine and getting inconsistent pressing, feed the seeds gradually.5. Clean After Every Use:

Oil residues can harden and affect machine performance. Always clean your oil maker immediately after use using a soft brush and dry cloth.6. Use the Right Seeds for Cold Press:

Cold-pressed oils are in great demand due to their richness in nutrients. Use seeds like flax, sesame, sunflower, groundnut, and coconut for the best cold-pressing results.7. Preheat Hard Seeds:

The harder seeds need to be slightly preheated before pressing. It improves oil extraction efficiency.8. Separate Oil and Residue Properly:

After extraction, allow the oil to settle for a few hours so that the residue can settle at the bottom.9. Store Oil in Dark Glass Bottles:

Sunlight can decrease oil quality. To preserve freshness, use dark-colored glass bottles or stainless steel containers.10. Label Your Oils:

In case you are doing the extraction of different oils, it would be a good idea to label the bottles with the date and seed type. This way, you will be able to notice the changes in both the freshness and the taste that occur over time.11. Use the Oil Cake:

The oil cake left over should not be thrown away; it is very nutritious and can be used for livestock feed, compost, or even the making of healthy snacks.12. Give Your Machine a Rest:

The oil maker should not be used continuously for long hours. If working for 45-60 minutes, cool it down for about 15 minutes so that the motor does not get overstressed.13. Keep the Machine on a Flat Surface:

The operation should be done on a flat and firm surface at all times to prevent vibration and to ensure proper functioning.14. Use the Right Mode and Settings:

If your oil maker comes with different modes or temperature settings, consult the user manual. It might be that a different speed and temperature are needed for each seed type to achieve maximum yield.15. Avoid Wet Hands and Surfaces:

Always use the oil maker with dry hands to prevent electric shock or malfunction. Water and oil equipment do not get along!16. Regular Maintenance Is Key:

The pressing barrel and motor parts should be inspected regularly. If required (per the manufacturer's instructions), apply lubricant to the moving parts to keep your machine at its best performance.17. Don’t Mix Different Seeds Together:

One kind of seed should be extracted at a time. Mixing may change flavor, texture, and the amount you get, especially when one seed has higher oil content.18. Experiment in Small Batches:

With a new seed, the best practice is to begin with a small quantity. It’s learning the oil output, pressing time, and flavor before moving to large-scale production.19. Read the Instruction Manual Carefully:

Each oil machine for home making oil works in a way similar to another but with minor differences. The practice of reading the manual thoroughly will help you avoid mistakes and will also help you increase the machine’s lifespan.20. Enjoy Fresh Oil Responsibly

Freshly pressed oil is strong and pure. Proper storage is required, and a period of 30-45 days is recommended for the best taste and health benefits to be consumed.A complete guide of How To Prepare Your Oil Press For Safe And Efficient Operation

Reasons Why You’ll Love Making Oil at Home

oil making machine for home always comes with the advantage of saving money but it is also about the healthy lifestyle that one is adopting. Supermarketoils are very often mixed with preservatives, chemicals, or refined additives that remove even the last trace of nutrients from the oils. With a home oilpress, you get:- 100% pure and natural oil

- No preservatives or adulteration

- Full control over ingredients

- Better flavor and aroma

- Savings in the long run

Conclusion

One of the smartest health investments you can make is using an Oil Maker Machine For Home. It gives you the power to decide what goes into your food while helping to sustain the environment. Not only will you be able to prolong the life of your machine by applying these 20 expert tips, but you will also be able to take advantage of the daily consumption of fresh, aromatic, and nutrient-packed oils.

Advantages Of The Mini Oil Pressing Machine

Cost financial savings:

Some of the most incredible benefits of the Best oil-making machine for home use are with considerable reductions in cost. Certainly, it will seem to cost a lot to purchase it; however, in the long run, it will actually pay for itself. Oil-making at home is a bigger price saver in comparison to going out every time to buy expensive oils commercially marketed with so much price markup.Quality control:

The important side is that an affordable oil maker machine for small business use and home use gives one the ability to maintain full control over the quality of the oil. At home, you choose your raw materials and only use high-quality organic ingredients in order to have a healthier oil with better taste, free from artificial additives and harmful chemicals.Quality and Flavor Preservation:

Those homemade oils keep the goodness freshly extracted, saved from in the shelf long enough to lose their flavors and aromas, and this quality in turn enhances the culinary taste. In terms of food industry businesses, utilizing freshly extracted oils can significantly enhance their product quality, leading to increased customer satisfaction and loyalty.Customization:

Creating your own oil provides unparalleled flexibility to adapt the product according to your specific preferences. Ingredients and flavor combinations may produce different oil blends customized for their own use. This customization capability proves particularly advantageous for small businesses aiming to offer distinctive products to their customer base.Environmental Benefits:

Personal oil production can contribute positively to environmental conservation. One may conclude that the utilization of organic materials, along with the absence of harmful chemicals and preservatives, would lessen the environmental impact and contribute to keeping it sustainable.Health Advantages:

In general, homemade premium oils are healthy alternatives to commercial oils because they do not contain artificial additives. Besides this, homemade oils maintain most of their nutritional properties, such as vitamins and antioxidants that offer health benefits.Conclusion

In conclusion, the advantages of using a mini oil extraction machine for home use for making oils at a domestic and small commercial level come into being from the ability to minimize cost and maximize control of quality. Scrimping on oil-making equipment is just barren-minded. If you would like to save money, go green, or simply indulge in oils that taste the freshest and best, a quality oil maker machine is a must-have. Offered by Nilsan India, electric oil-makers are premium-grade equipment available at unbeatable prices.

1. Choose The Proper Place

An oil press has to be installed at a site chosen carefully. It should be placed on a strong, flat surface so as not to vibrate and in an environment that is clean and dry so that the quality of the oil is maintained. Moreover, the place has to be well ventilated to prevent overheating. Also, there has to be ample space available for the handling of materials, diffusion of oil, and cleaning of the equipment after its use.2. Checking the Power Supply

Most domestic oil press machine is primarily electrical in nature, though some manual or alternative models exist. For electric machines, careful precautions should be taken to ensure that the voltage is correct (for example 220V or 110V), the connection to the socket is never loose, the socket is not broken, proper grounding is implemented to avoid any chance of electric shock to any personnel from abnormally conducting parts, and a backup source is made available to counter outages so frequent in some areas.3. Inspect The Machine

Before operating the oil press, check it completely so as to avoid all kinds of problems. Confirm if all parts have been assembled correctly, ensure the nuts and bolts are tight to prevent vibrations, and lubricate the essential parts to make sure they work smoothly. Then, conduct a dry run to ascertain that everything works properly.4. Clean The Machine

Hygiene in oil extraction is of utmost importance to have the very pure oil and tests. Key practices are dusting both the inside and outside of the machine, making sure the chamber is clean of any leftover oil from the previous use, and using food-safe cleaners with lukewarm water for cleaning unattached parts when needed.5. Prepare The Raw Material

Raw material preparation is very important for oil extraction. High-grade seeds or nuts should be selected, avoiding any damaged or infested ones. Cleaning involves removing stones, dust, and other impurities that can damage the machine and contaminate the oil. Seeds must be dried to the required moisture content since excessive moisture lowers oil yield and causes clogging. Some seeds, like peanuts that need slight roasting before pressing.6. Pre-Heating Machine

Many modern machine comes with a pre-heating option to ensure efficient oil extraction. Adjust the temperature according to the type of seed. Allow the machine to preheat for 5-10 minutes.7. Keep The Collection Container Ready

Before a process of preparation, there should be appropriate containers ready. For keeping oil, it has to be clean and preferably stainless steel or glass, as plastic containers should henceforth be omitted. For seed cake, a separate container should be there, which may be used as either cattle feed or fertilizer. A filter cloth or mesh may be laid over the oil container for purification in case of need.8. Safety

Heat and moving parts of an oil press insist on stringent safety measures during operation. The most important points of precaution include wearing a pair of gloves and refraining from loose clothing while operating the oil press; keeping the press area fire-safe by means of extinguishers; preventing children from coming near the press; and taking all safety precautions as instructed by the machine manufacturer.9. Run With A Small Quantity

Hence, it is good practice to load the machine with a small batch of seeds for the proper functioning of the machine and the temperature of the seeds before loading the bigger quantity. In this regard, wastage will be prevented, and adjustments can be made where required.10. Record Keeping And Monitoring

In commercial oil press operations, it is important to keep records of seed input quantities, oil output for yield analysis, machine operating hours for maintenance, and temperature settings for different seeds in order to make operations more consistent.Conclusion

Preparation of the oil press is essential to the safety, smooth operation, and efficiency of the press. Washing and inspecting the machine, preparing the quality seeds, and observing safety guidelines all build up to ensure consistent performance and high quality oils. A well-maintained press will yield better results as well as longer equipment life. Preparing your oil press properly means peace of mind, healthier oils, and savings in the long term saving. Read more Article: How to Maintain Your Home Oil Machine for Long-Term Use

What Is an Oil Filter Machine?

The oil filter machine is socially designed for the removal of dust and impurities. It is engaged in ensuring the oil quality at the time of production, during storage, or when the oil is being put to use. The following are the areas for such machines:- In food processing industries, for filtering cooking oils.

- In automobile and industrial factories, for cleaning and lubricating oils.

- In the pharmaceutical and cosmetic industries, the cleanliness of oils directly affects product safety.

How does an oil filter machine work?

The simple goal of the oil filtering machine is to extract pure oil. It follows a step-by-step process for maximum filtration:- Oil Collection – Tanks or chambers are used for collecting the oil that requires filtering.

- Pre-Filtration Stage – It will remove dust, sludge, and sediments.

- Fine Filtration – The specific filters remove impurities like carbon deposits, chemical residues, and traces of water.

- Polishing Stage – filtering gives clarity and shine to all.

- Storage or Re-Circulation – The filtered oil is stored in a clean tank, or it finds re-circulation in machinery for use.

Why Oil Purity Is Important

We should keep oil clean because contamination can lead to many problems, some of which may be irreversible or very costly to repair. The need for purity, therefore, arises due to the following reasons:- For Edible Oils – Unfiltered oil may contain toxic substances, bad odors, and unpalatable taste. Cleaned oils provide superior storage qualities as well as safety of use.

- For Environmental Protection – Clean oil reduces waste and prevents the release of harmful pollutants.

Advantages of an Oil Filter Machine

Better Quality of Oil

The foremost benefit is that the instantaneous quality has remained fresh, clean, and functional. Filtration does indeed raise the quality, be it edible or industrial oil.Cheaper Production

Recycling of the oil by purifying it lets the industries save a lot of Cost, which would have gone into continuously replacing the oil.Increased Machinery Life

Clean oil lessens the wear and tear of engines or machines and extends the lifespan of such units.Health and Safety

Filtering of edible oils is done the prohibit any harmful residues from coming in contact with the consumer. As far as industrial oils are concerned, they ensured people in the workplace from hazardous accidents stemming from equipment failures.Making the Environment Friendly

Oil filtration reduces the amount of waste generated and facilitates recycling, hence promoting the environmentally friendly approach of industries. Explore the range of: Oil Filter Machine and ConveyorApplications Across Industries

The oil purification machine has a myriad of areas of application, providing utility in several industries:- Food Industry – Restaurants and plants value the filtration as a way to extend the life of their cooking oil.

- Pharmaceuticals and Cosmetics – Here, purity represents a fundamental issue, where oils are used in drugs, creams, and ointments.

Selecting the Right Oil Filter Machine

While choosing an oil purifier machine, keep the following points in mind:- Type of Oil – Cooking, lubricating, hydraulic, or cosmetic Oil.

- Capacity – Depending upon the quantity of oil to be purified daily.

- Filtration Level – Some applications require filtration at a micro level.

- Ease of Maintenance – Systems with a replaceable filter that can be cleaned without difficulty work best.

- Energy Efficiency – Go for the ones that consume the least energy and have the most output.

Maintenance Tips for an Oil Filter Machine

Proper care should be taken to achieve maximum efficiency. Here are these tips:- To keep the air filters clean by regularly cleaning/replacing them.

- Check for any oil leakage through the pipes or the tanks.

- Arrange inspections regularly to avoid any breakdown.

- Operate the machine as recommended by the manufacturer.

- Store the machine in clean and dry conditions.

- Regular cleaning would keep the machine running and keep producing pure oil.

Future of Oil Filtration

With increased awareness concerning health, safety, and sustainability, the demand for Oil Filter Machines shall just increase. They hold the potential to become energy-efficient, space-saving, and easy to operate. Intelligent filtration systems are now being designed, incorporating sensors for real-time oil quality analysis. Such evolutions ensure that both households and industries can always procure clean oil while minimizing waste and conserving the environment.Conclusion

Oil purity is not only a quality issue but also an issue of safety, efficiency, and sustainability. The Oil Filter Machine is an indispensable Appliance that guarantees each drop of oil — whether for cooking, lubrication, or hydraulics — is clean and effective. With an investment in an Oil Filter Machine, you protect your health, prolong the life of your equipment, and contribute to creating a cleaner world. It is a vital tool that guarantees purity, dependability, and tranquility with each drop.

What Is a Domestic Noodle and Pasta Maker?

A home pasta and noodle maker machine is a kitchen gadget that assists in making noodles or pasta fresh every time. Making pasta meant combining flour, eggs, and water into dough that was gently mixed by hand before being rolled out and cut into desired shapes. This, of course, takes time and energy. Conversely, a pasta machine mechanizes part of this process. Depending on the type, they can:- Mix and knead dough (electric models).

- Roll out pasta sheets to a uniform thickness.

- Cut pasta or noodles to forms such as spaghetti, fettuccine, lasagna sheets, or flat noodles.

There are mainly two types of home pasta-making machines

- Manual Pasta Makers – They are hand-crank operated and mostly work on rolling dough into sheets and cutting into simple shapes.

- Electric Pasta Makers – They carry out many more production steps like mixing, kneading, and extrusion, and are easier to use for regular production.

How Do Domestic Noodle And Pasta Maker Work?

Pasta-maker operation depends on its kind. A hand machine needs dough to be prepared separately. Dough, once prepared, is then passed through rollers, which flatten it to slicing. Electric machines usually have mixing and extrusion functions inside. The user puts ingredients into the machine, and the pasta maker will do everything else: make dough, extrude, and cut it to shape. Extrusion machines usually come with exchangeable discs, allowing different kinds of noodles and pasta to be made. Given this flexibility, they are used for Western as well as Asian cooking.Why the Domestic Pasta Maker?

1. Freshness and Quality

Domestic pasta maker-made pasta and noodles are usually fresher and tastier when contrasted with store-bought ones. The user can dictate the ingredients, in which case no preservatives or additives are necessary. This leads to a healthier product.2. Customization

Using a domestic pasta maker, one can experiment with different flours-from whole wheat to semolina to gluten-free. This becomes helpful when there is a personal need or restriction as far as diet is concerned.3. Consistency

Pasta cut and rolled by hand can produce uneven results. Even cooking and improved presentation result from the even thickness and shape that a pasta maker ensures.4. Convenience

Making pasta has always required a lot of effort and time, but home appliances make the task easier. For instance, electric models are so simple that even a beginner can successfully make pasta.Benefits of buying a Domestic Noodle and Pasta Maker

Health and Nutrition

When you make pasta at home, you control its ingredients, so you can accommodate certain dietary restrictions. For example, you can decrease salt levels, use organic flour, or add vegetables and herbs to enhance its nutritive value.Cost Saving

After buying the pasta maker, it will save you a few bucks on the long term. Buying fresh pasta from stores or restaurants tends to steal much from your pocket, while homemade pasta is always available at cheaper prices.Culinary Creativity

A pasta maker opens a wonderful avenue of experience for any kitchen lover-who shall be inspired to tweak recipes, experiment with flavor profiles, and come up with different ways of presenting noodles or pasta.Family Bonding

It can be a fun family experience to prepare pasta at home. Children might be involved in choosing shapes or putting dough through a pasta machine, making the entire cooking process a family affair. Buy Nilsan Pasta Noodle Sevai Maker (EPS-NM01) at an affordable price.Types Of Dishes You Make with a Domestic Noodle And Pasta Maker

Making any one of an infinite variety of dishes would be afforded by a home pasta and noodle machine. A few common examples are:- Spaghetti and meatballs – An Italian relationship enhanced by the freeing of fresh pasta.

- Fettuccine Alfredo – Wide ribbons of fresh pasta perfectly complement creamy sauces.

- Lasagna – Fresh sheets of pasta bring grittiness and value to this layered wonder.

- Asian noodles – A noodle stir-fry here, a noodle soup there-wheat noodles all have their place with the pasta maker.

- Stuffed Pasta – Ravioli or tortellini could be made from fresh sheets of pasta made by the pasta maker.

Space and Storage

Pasta makers come in different sizes. Miniature models fit into a small kitchen better.Ease of Cleaning

A sticky dough is a must to be kept away while cleaning. Some machines come with removable parts that are much easier to clean.Price Range

Conversely, manual models usually come at way of cost. The convenience of electric models is certainly the price to pay. It would be worth considering how often you will use it in the long run compared to the price you will pay initially.Why They Are Becoming Popular

With the increased frequency of homemade foods, it has become typical for households to invest in equipment that facilitates their working toward the preparation of meals of excellent quality. Healthier eating and fair taste have been the major factors behind the demand and popularity of home pasta makers. As more and more households appreciate the importance of fresh home food, pasta makers cease to be seen as gadgets for the rich and become helpful kitchen appliances.FAQs

1. What is a pasta maker used for? A pasta maker was designed as an instrument of the kitchen to ease the preparation of fresh pasta. It rolls, cuts, or extrudes dough in different shapes such as spaghetti, fettuccine, or lasagna sheets. Some varieties also mix and knead the dough automatically-the whole working process now gets quicker and equally consistent. 2. Is a pasta maker worth it? A pasta maker certainly makes a worthy purchase, particularly for any cook who regularly enjoys fresh pasta. It gives you control over ingredients, ensures consistency of texture, and can earn out in cost over buying fresh pasta from stores. 3. Do you use a pasta maker to make noodles? Yes, pasta makers can prepare noodles as well. Depending on what kind of machines it is and which cutting or extrusion attachments come along with it, you can manufacture a wide variety of noodles suitable for both Western and Asian cuisines. 4. Is making pasta at home healthy? An alternative, healthier homemade pasta could be a healthier alternative to a store-bought one because you control the ingredients. You could opt for whole wheat or gluten-free flours, add some vegetables or herbs on top of that, while avoiding any preservatives and additives much healthier choice for your diet. Read more about kitchen innovation tool: Best Mini Oil Press Machines In India: Top Brands & Where To BuyConclusion

Noodles and pasta makers allow one to quickly and conveniently integrate the making of fresh homemade noodles or pasta into daily life. These are machines that took away the manual labor of an otherwise very time-consuming task, enabling anybody from novice to experienced chefs to craft delicious noodles and pasta right at home. Fresher, control, and cost-effectiveness in the long run.

Oil press machine maintenance and cleaning practice

Look at how to maintain oil press machine, which involves regular cleaning: effective cleaning gets ignored. Every seed and nut leaves behind some residue. This small amount builds up in the pressing chamber and spout, creating blockages and reducing the quality of the oil produced. Here are some useful oil press machine cleaning tips for everyday use:- Wipe exterior surfaces: Wipe away any residue left on the machine’s surface from oil and seeds immediately after use.

- Flush the Press Chamber: Remove any deposits with warm water or food-grade cleaning oil.

- Clean Filters: Check the filters daily and wash them to avoid clogging.

- Dry Thoroughly: Parts must be air-dried after cleaning, as excess moisture inside the machine can promote rust and mould.

Long-Term Servicing Guide

In addition to daily cleaning, the machine requires periodic cleaning to prepare it for extended use. A structured oil press machine servicing guide can save you from unexpected downtime.- Lubrication: parts should be cleaned with lubricants of the kind recommended by the manufacturer to reduce wear and tear.

- Examine belts and gears: for slack, cracks, or even loud operation. Fixing parts earlier can save you from bigger issues later.

- Look over the motor: Verify the electrical connections and make sure they are firm and free of dust or oil.

- Temperature monitoring: Mini commercial oil press machines or heated presses require a certain temperature to function safely. Make sure that the sensor and heatingare working properly.

- Professional servicing: Depending on how frequently the use is, schedule full checkups with a technician once every 6–12 months.

Proper Maintenance of an Oil Press Machine

-

The most effective way to maintain an oil pressing machine is to perform consistent daily upkeep and servicing,

coupled with attention during operation. Here are the best way to care for oil press machine:

- Use appropriate raw materials: using overly hard, wet, or dirty seeds, which pose a risk to the machine.

- Run at capacity: overloading the machine beyond its rated input — it safeguards the motor from excessive strain.

- Store properly: Put your machine in a dry, cool place, protected an oil press machinefrom direct sunlight and moisture.

- Read the manual: Every model, whether commercial oil press or small unit, has particular care guidelines. Always refer to the manufacturer's instructions.

Tips to Extend the Life of Your Oil Press Machine

To extend life of oil press machine, these small changes can make a significant difference. Look into the additional recommendations:- Remove Dust from Seeds and Nuts— and seeds should be free of dust, stones, or shells before pressing. Such wastes cause friction and damage within the chamber.

- Avoid Overheating—Give the press a break if the machine is too hot. Overheating may damage internal parts and reduce efficiency.

- Worn parts: Timely Replacement —Blades, filters, and seals deteriorate with repeated usage. Timely replacement saves you from bigger issues.

- Keep Spare Parts Ready—If you use a commercial oil press, having spare belts, filters, and sensors saves you from prolonged stoppage.

- Frequent Updates of Software (if applicable)—Newer models of automated oil press machines may have digital controls. Update them for continued smooth functioning. Following these guidelines helps implement preventive maintenance, which safeguards your machine and facilitates consistent oil production.

Conclusion

In conclusion, oil press machine maintenance is crucial for its long-term business success and efficiency. Regular cleaning, maintenance, and proper use ensure the machine provides optimal performance for years to come. Whether you use a cold oil press machine for nutritional oils, a mini commercial oil press machine for small businesses, or an industrial-strength commercial oil press for large-scale production, proper maintenance is essential for maximising your investment.

Understanding Cold Press Oil Extraction

Cold pressing usually refers to a mechanical process of extracting the oil by pressing the seeds or nuts at controlled low temperatures. Unlike the traditional or solvent-based methods, which involve the use of high heat and chemical solvents, cold pressing keeps the temperature under 50°C right from the start of the extraction process, thereby ensuring that the oil retains its natural flavor, aroma, and nutritional essence. A cold press oil expeller works through the application of pressure by the screw mechanism on the raw material, with minimal release of heat or without the use of any chemical additives. The machines are widely applied to extract oil from seeds like sesame, sunflower, mustard, coconut, groundnut, and flaxseed.Nutritional Benefits of Cold Pressed Oils

One of the greatest advantages of cold press oil expellers is the preservation of nutrients. Heat and chemical treatment have the potential to destroy or break down essential compounds present in the oil, such as essential fatty acids, antioxidants, vitamins (like vitamin E), and phytochemicals. Cold pressed oils preserve a greater percentage of these nutrients since there is no application of excessive heat in the process. The resulting oils are normally full of:- Omega-3 and Omega-6 fatty acids

- Vitamin E

- Polyphenols and other antioxidants

- Natural enzymes

Purity and Quality Control

The cold pressing process produces oil in its purest and natural state. Since no chemicals or solvents are applied in the extraction, the oil itself is free from synthetic impurities. This produces a healthier and safer product that can be consumed for extended periods of time. Additionally, the process decreases adulteration chances. Since cold press oil is less processed, manufacturers tend to have tighter controls on sourcing, manufacturing, and packaging. This makes traceability better and quality control possible in a better manner.Environmental and Economic Sustainability

Cold press oil expellers are also a more eco-friendly alternative. Conventional methods of extracting oils, particularly chemical solvent-based processes, are inimical to the environment. Such processes tend to involve a lot of energy inputs and leave behind chemical waste, which should be disposed of with caution. Conversely, cold pressing is a cleaner and more energy-conservative method. Numerous expeller machines are built to be small, low-maintenance, and able to operate with little water and electricity. Economically, cold press oil extraction is feasible for small and medium-sized firms as well as for household or community production. The machinery can be operated with minimal technical know-how, and maintenance is minimal. Cold press expellers thus provide an interesting option for local economies and rural development.Applications Across Industries

Although cold press oil expellers are widely linked to the food sector, their uses are more diverse than merely culinary applications. Cold press oil expellers are also utilized in making:- Cosmetic and skin care products – where pureness and nutrient value are paramount

- Pharmaceuticals – particularly for the processing of herbal and plant-based medicines

- Aromatherapy oils – where chemical-free extraction is paramount to product effectiveness

Consumer Demand and Market Trends